Heat transfer foil film so-called Heat Transfer Film printing is to use a heated roller to transfer the ink onto the product which can befor plastic, glass or metal.

Feature of Heat Transfer Film

Gravure printing presents delicate full color by applying pearl, metallic ink and metallization not only enhanced the product value but also kept competitive cost while mass production.

The practical application of Heat Transfer Film

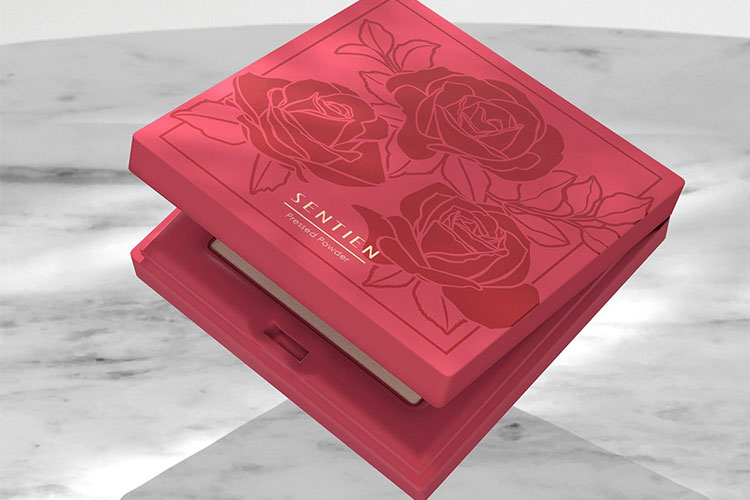

Heat Transfer Film printing technology can be printed on a variety of materials (most common for plastic), so it has a wide range of applications, including Housewares, stationeries, cosmetics, appliances and janitorial, all can use this printing technology to make the utensils more beautiful and shiny. SENTIEN is a professional supplier of Heat Transfer Film materials, providing you with the highest quality film in the world.

HTF Effects

Glossy / Matte

Colorful

VM

Super Matte

Antibacterial

Partial Matte

Program

The raw material of Heat Transfer film is

PET film ( the thickness is 19um/23um/36um/50um)

The heat transfer film of Sentien printing factory

almost applicated in plastic products, such as cosmetic containers, toys,

electrical appliances, building material, stationery, houseware..etc (general

plastics are available)

The heat transfer machine will adjust different

temperature and pressure according to difference products, then transfer the

ink of heat transfer film on the plastic products.

According to the appearance of products to adjust the transfer of temperature, pressure, speed.

The main transfer require the interactive

adjustment of these tree paraments and the quality of the fixture is also an

important key to the success of transfer.

The transfer temperature need higher than

injected raw plastic.

For explain PP material is 180 degrees Celsius, ABS is 200 degrees Celsius up) and the speed of transfer is also another important interactive adjustment.

According to the size of transfer plastic

and design.

2. the product will use transfer film for check the template (diecut size)

The heat transfer machine mainly uses a heated rubber wheel (plate) (usually cylindrical or flat) to form a high temperature condition on the transfer object.

And the direction of pressure of the rubber wheel (plate) needs to be in line contact with the transfer object or plane contact.

If it cannot be adhered to the transfer

object, the effective transfer effect cannot be achieved, so the non-planar

shape cannot be transferred.

For

metal need to warm up before transfer and also need to keep the high

temperature after transfer for some time.