Core Technology

Sentien has four different processes to do the surface decoration as well as six core technologies to ensure the quality of our products. Sentien has earned the trust from customers and became the nominated suppliers for various global brands.

| Technology / Product | IMR | INS | HTF | IML |

|---|---|---|---|---|

| Printing | ||||

| Coating | ||||

| Graving | ||||

| Laminating | ||||

| Molding | ||||

| CMF |

-

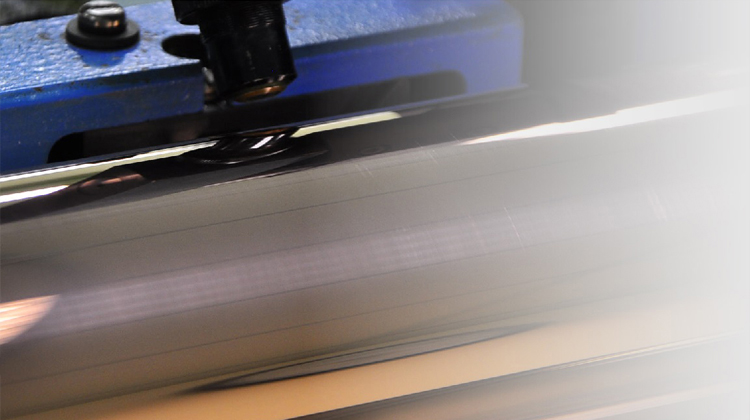

Printing

Gravure printing is the most common process in printing industry which can apply on PET, OPP and PE film.

Features:

1. Able to print the product continuously and maintain in high quality.

2. Able to perform the details of the pattern itself.

3. Able to lower the cost for after mass production. -

Coating

Film that used to print by Sentien applies functional coating to modify the property of the substrate.

e.g. Function with Glossy, matte, soft touch, corrosion resistance, abrasion resistance, and so on. -

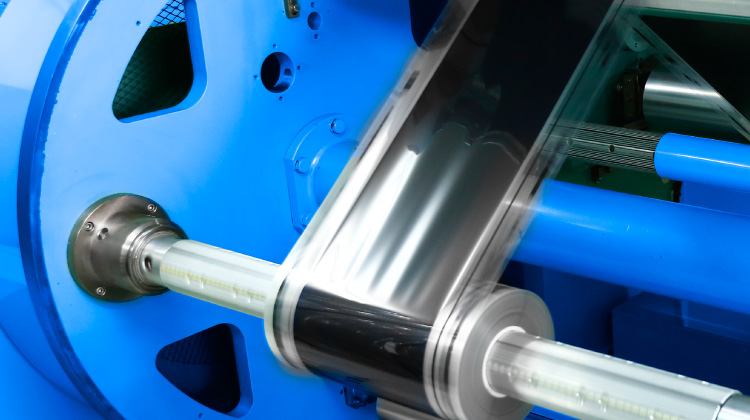

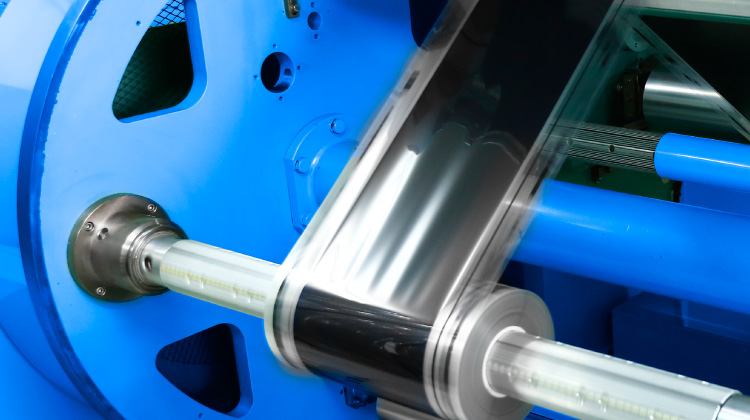

Graving

Cylinders are mad by iron or aluminum with copper plated on the surface. Sentien makes the pattern on the cylinder by using diamond cutters, laser or chemical etching.

-

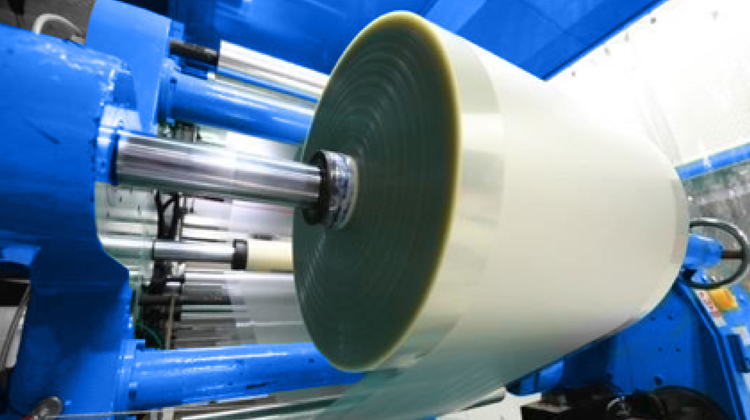

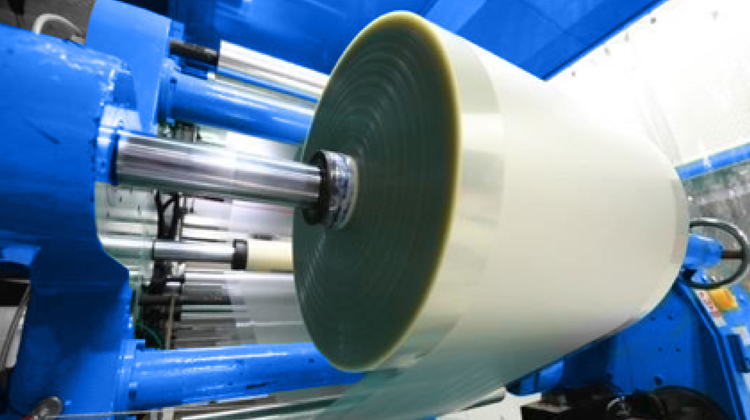

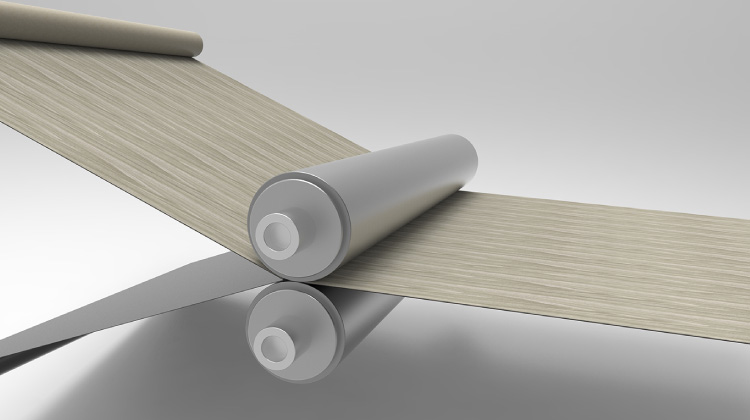

Laminating

Laminated technology enables single material changes its characteristic and enhance the ductility, stability, appearance, as well as specificity. It can convert into permanent material by heating, pressuring, various adhesives and specific manufacturing process.

-

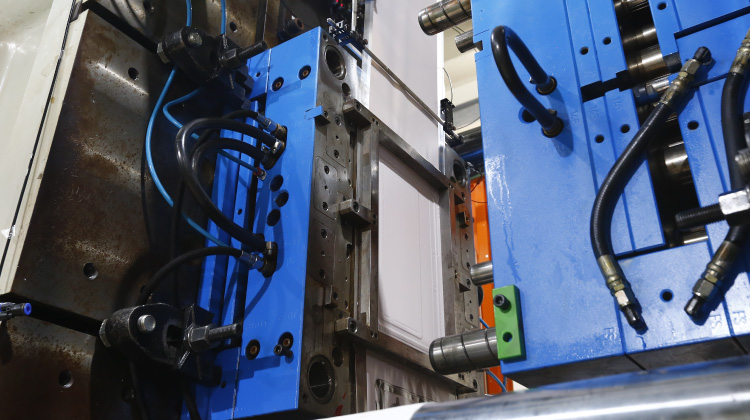

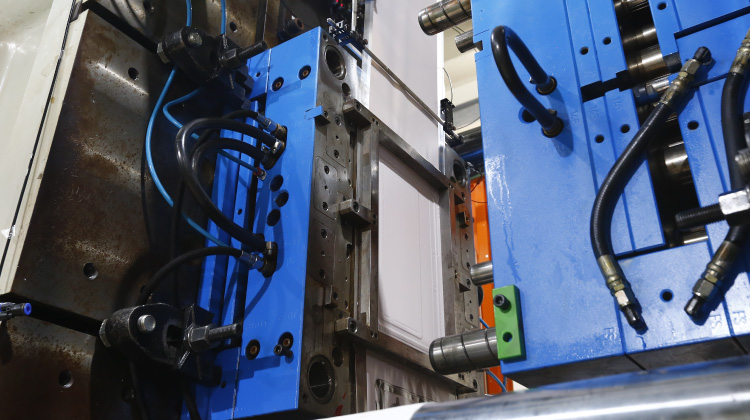

Molding

IMR- Insert the film into the mold and apply the foil feeding machine to ensure the accuracy of the film. Inject the plastic to make molding and surface decoration done simultaneously.

IMF- Apply the laminating technology on the film to enhance characteristics in demand. Preheating and shaping the film before insert the mold to make molding and surface decoration simultaneously. -

CMF

Customize the design based on the process of IMR & INS. Provide the trend of designs to customers with various color and sense of touch.